Description

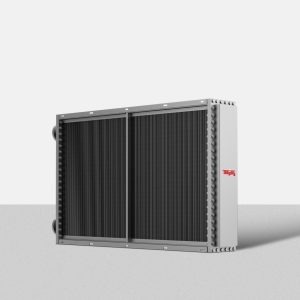

Steam Generating Heat Exchanger

Discover the Power of Pure Steam!

TANPERA Steam Generator Heat Exchangers utilize heat from energy sources to produce completely clean steam throughout the process. Thanks to its advanced design, all surfaces that the steam comes into contact with are made of stainless materials, ensuring safe use in applications where hygiene requirements are critical. Offering high energy efficiency and durability, these exchangers add value to industrial processes with long life and uninterrupted performance.

Technical Specifications

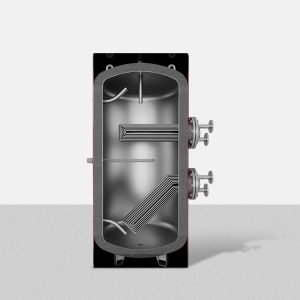

- Material: Stainless steel (AISI 304/316).

- Operating Temperature: Up to 400°C.

- Basınç Dayanımı: Up to 40 bar.

- Design: Body tubular structure, high heat transfer surface.

Working Principle

- Pure Steam Production: The heat energy of energy sources such as dirty steam, hot oil or hot water is used to vaporize water.

- Hygienic Design: The surfaces that the steam comes into contact with are completely made of stainless material, which prevents the formation of any contamination.

Continuity: Clean steam production is continuously maintained throughout the process, which is suitable for precision production requirements.

Advantages

- Full Hygiene: No risk of contamination and contamination thanks to stainless surfaces.

- Energy Efficiency: Saves energy with its high heat transfer coefficient.

- Longevity: Its durable structure ensures long-term use.

- Suitable for Sensitive Industries: Reliable performance in sensitive industries such as food, pharmaceuticals and chemicals.

- Easy Integration: With its compact design, it can be easily integrated into existing systems.

Application Areas

- Food Production: Hot steam production under hygienic conditions.

- Pharmaceutical Industry: Meeting the need for sterile steam.

- Chemical Industry: Processes requiring clean steam.

- Energy Facilities: High quality steam production for steam turbines.

- Facilities with Hygiene Requirements: All industrial plants that need clean and sterile steam.

TANPERA Steam Generator Heat Exchangers allow you to optimize your processes by maximizing hygiene and reliability standards.