Description

What are Shell&Plate Heat Exchangers?

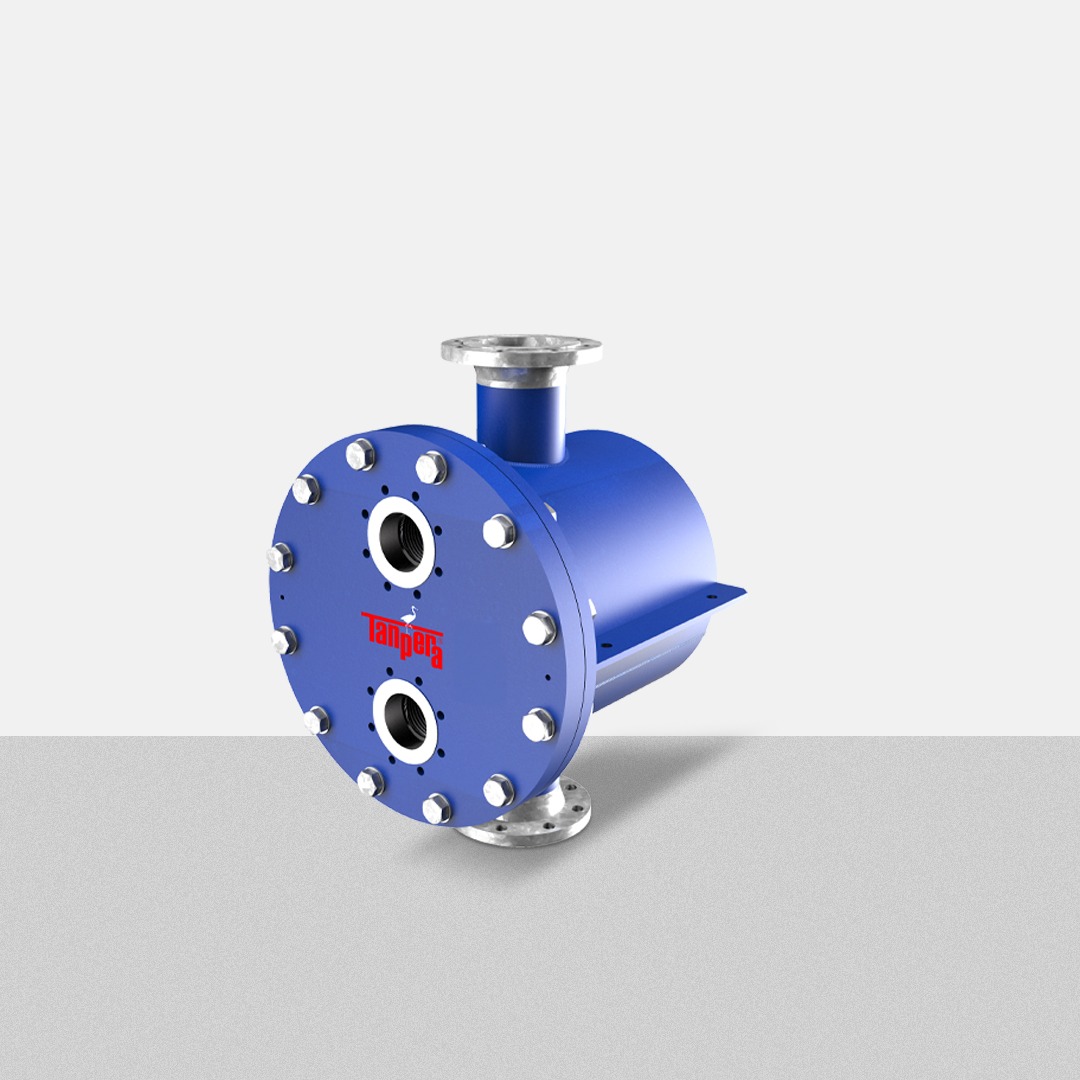

Tanpera Shell&Plate Heat Exchangers are specially designed to meet the heat transfer needs of demanding fluids. These heat exchangers provide reliable heat transfer under high temperature and pressure conditions thanks to spiral plate coils embedded in the core and shell. They are an excellent solution, especially in systems where particulate, viscous or fiber-containing fluids pass through.

The heat exchanger’s wide channel design allows free movement of particles, minimizing the risk of clogging. This ensures uninterrupted and efficient operation even under harsh conditions.

Working Principle

The working principle of Shell&Plate Heat Exchangers is based on the circulation of fluids between the shell and the plate to transfer heat. The wide channel design allows high viscosity or particulate fluids to move freely. The spiral plate design encourages turbulent fluid movement, which increases heat transfer efficiency.

While the fluids move in separate channels without mixing with each other, heat transfer is realized with minimum energy loss despite high temperature differences. This structure provides the advantage of energy saving and long-lasting use.

Advantages

- High Efficiency: Spiral plate design ensures maximum heat transfer.

- Anti-Clogging Design: Wide channels allow free movement of particles, preventing clogging.

- Durability: Optimized construction for dirty and high viscosity fluids.

- Energy Efficiency: High performance with minimal energy loss.

- Versatility: Design to suit the needs of different industries.

- Easy Cleaning and Maintenance: Cleaning and maintenance is easy thanks to the modular structure.

With Tanpera, Challenging Fluids Can Now Be Easily Managed!

Tanpera Shell&Plate Heat Exchangers make a difference in the industry in terms of energy efficiency and durability, offering high performance even in the most challenging conditions. Thanks to its wide channel design and innovative structure, it offers an ideal solution for dirty, particulate or viscous fluids.