Description

What is an Evaporator?

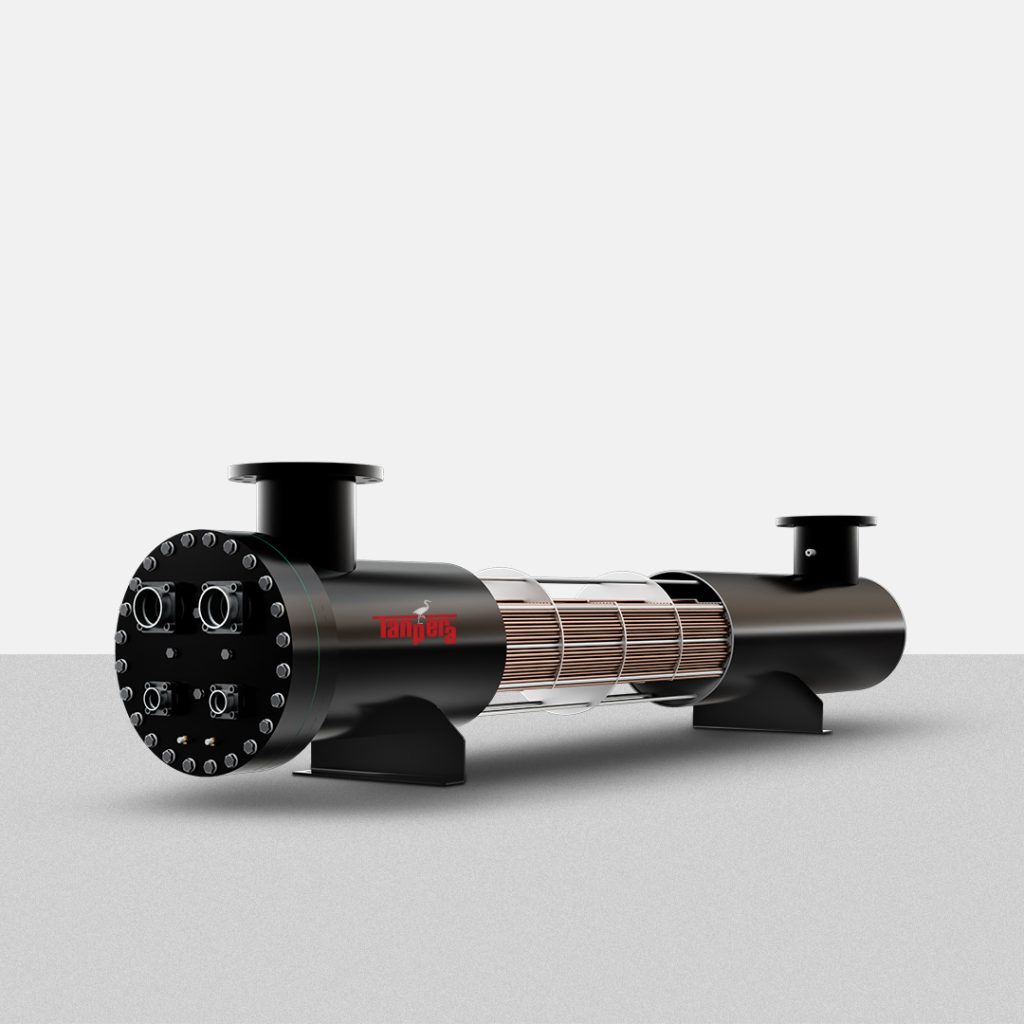

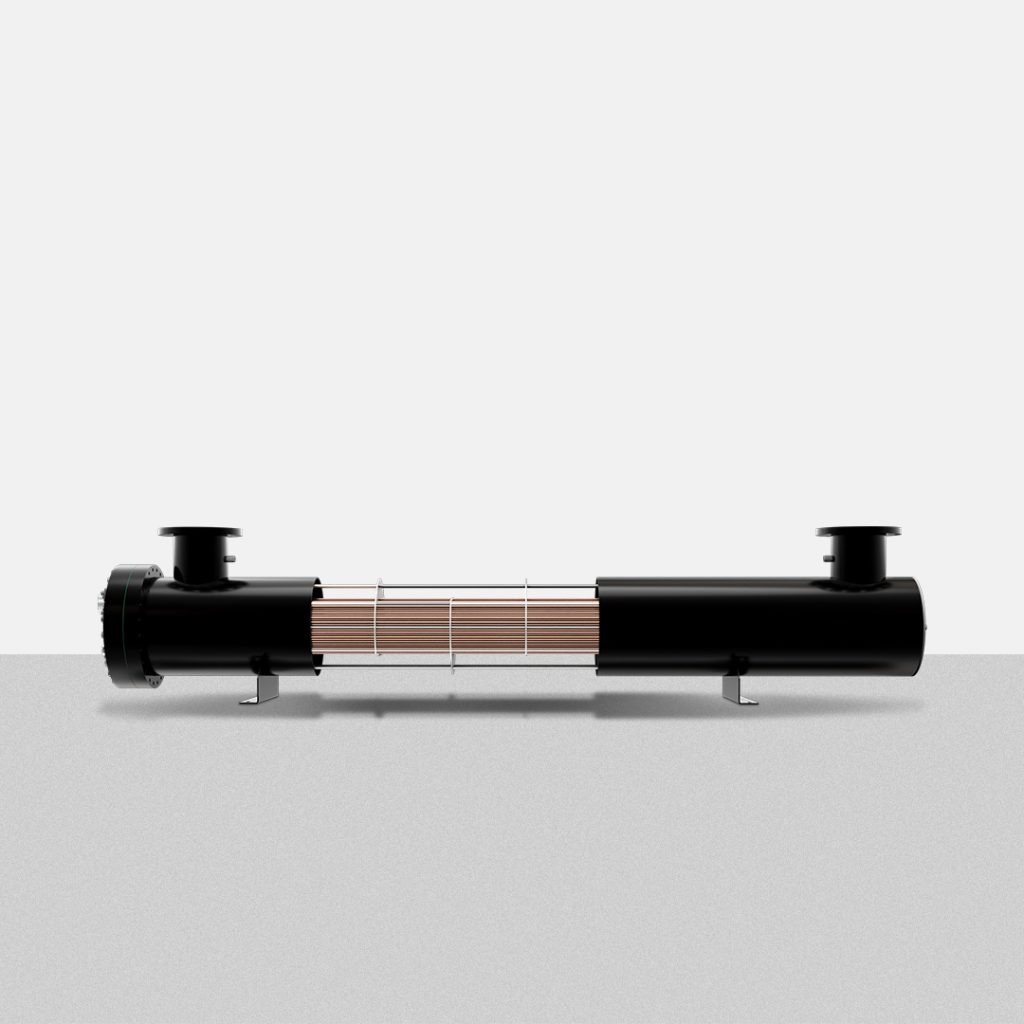

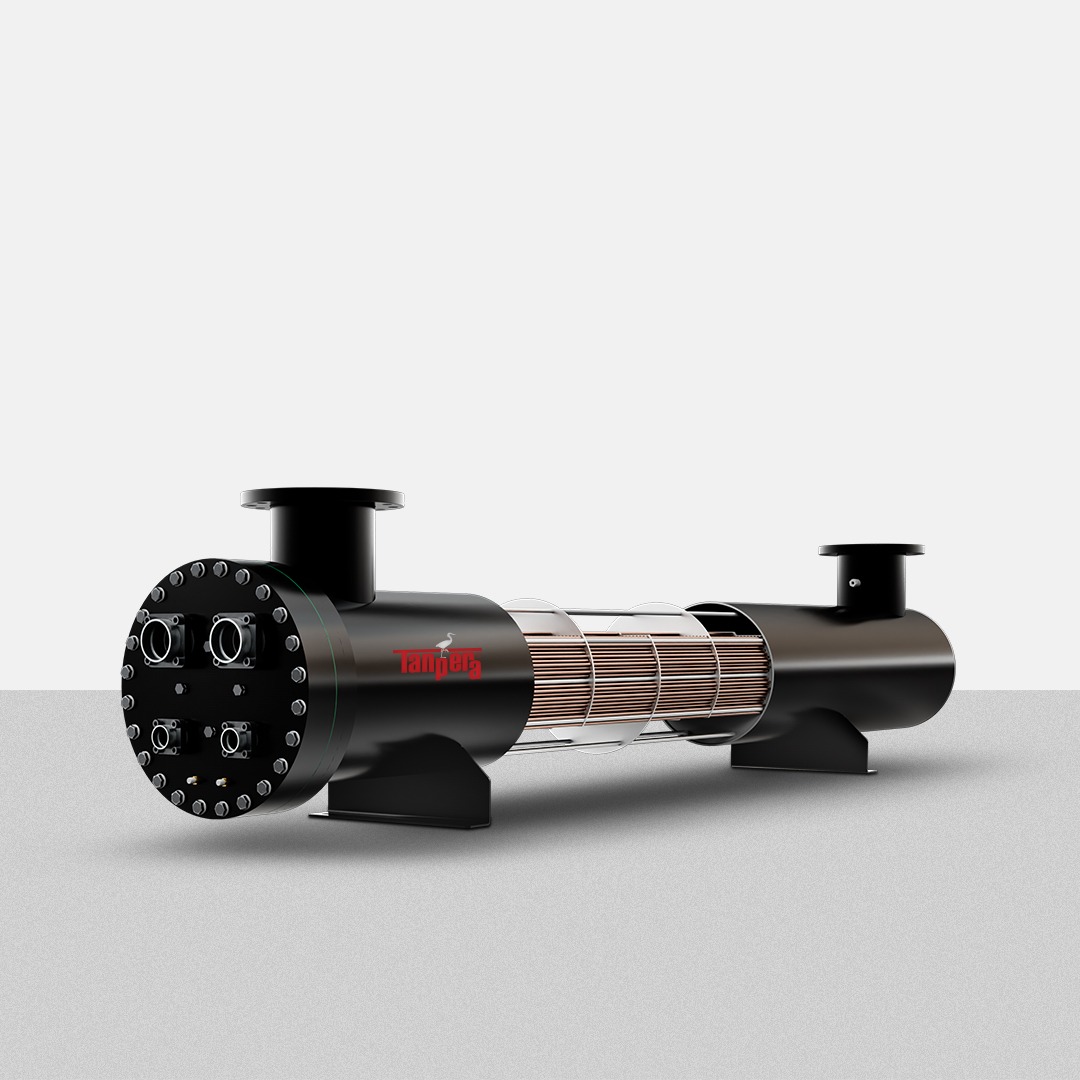

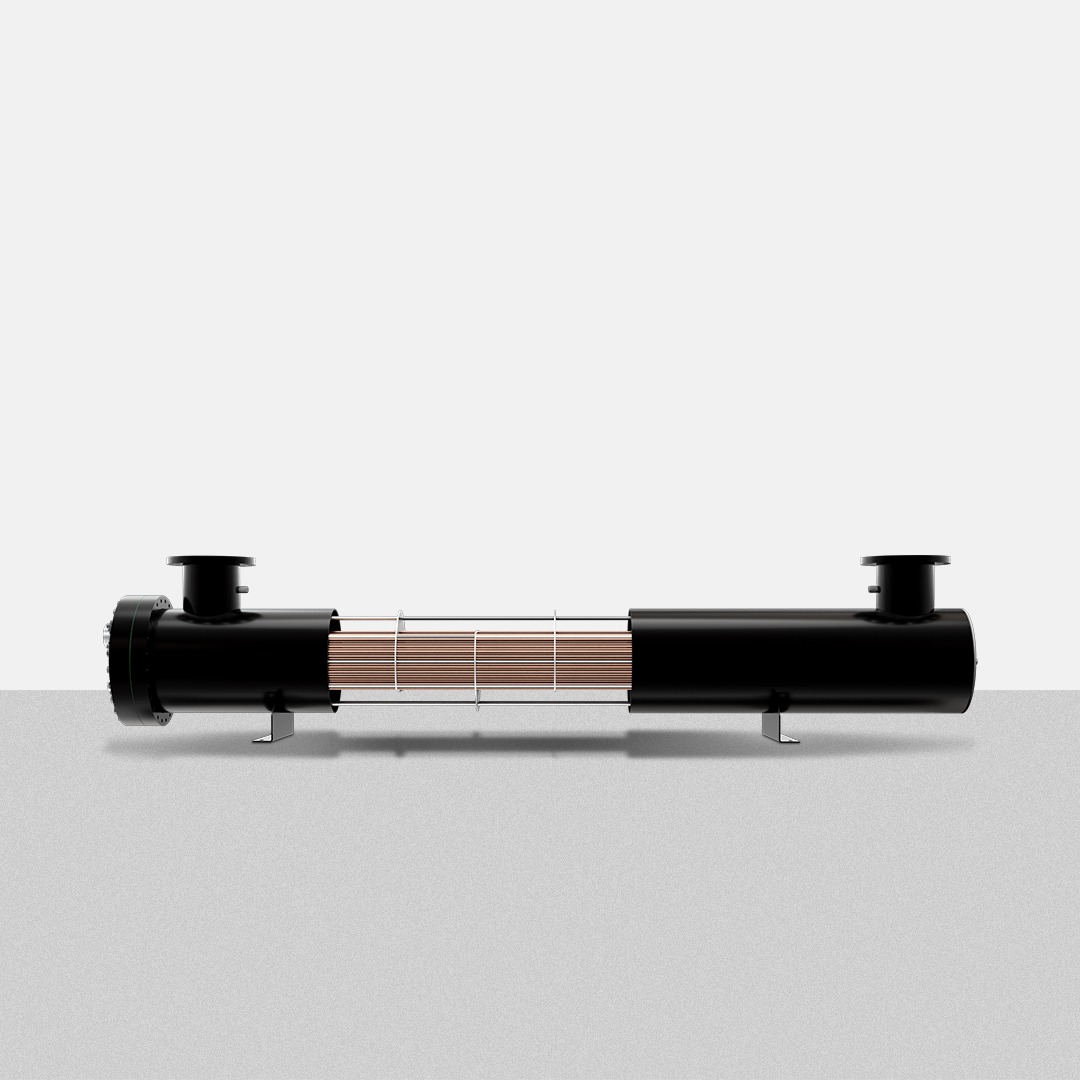

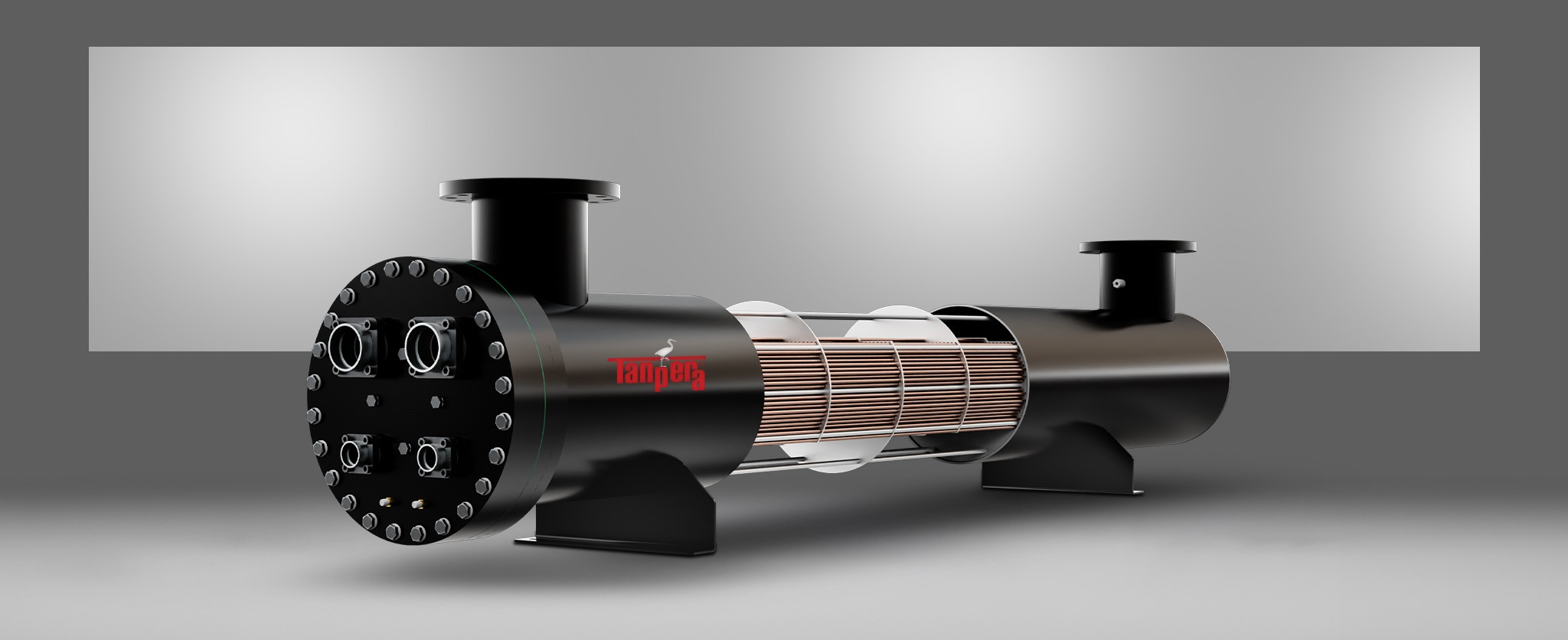

The heat exchanger that acts as an evaporator used in heating or cooling systems is called an evaporator. Evaporation systems consist of 4 main components to complete the cooling cycle. These components are divided into 4 groups as compressor, condenser, expansion valve and evaporator. The compressor increases the gas pressure and temperature by compression and transmits it to the condenser. The hot and high pressure gas delivered to the condenser is condensed from the condenser and delivered to the throttling valve with some pressure drop. The gas delivered to the throttling valve passes through the throttling valve and the gas temperature is reduced together with the gas pressure. The gas-liquid mixture coming out of the throttling valve is delivered to the evaporator, where the refrigerant is completely returned to the gas phase and delivered to the compressor. In this way, the gas cycle is completed.

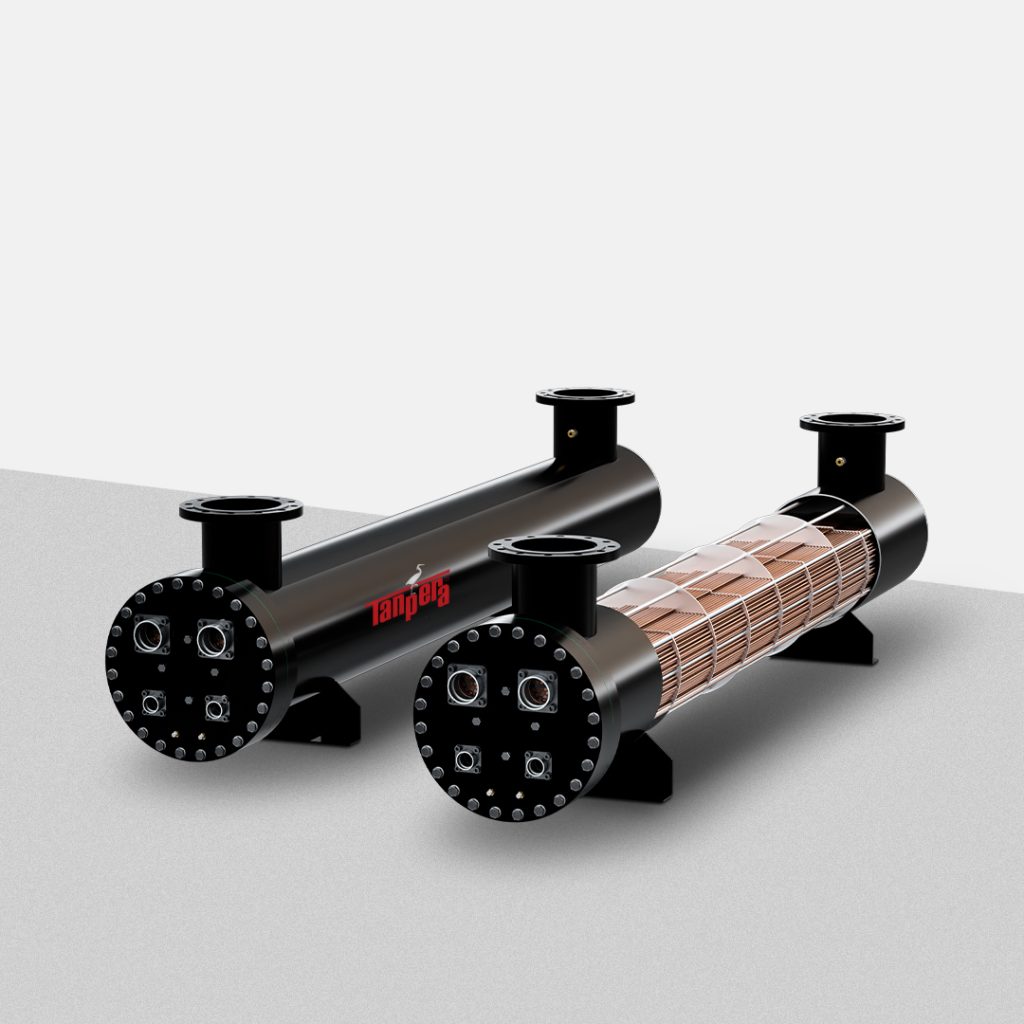

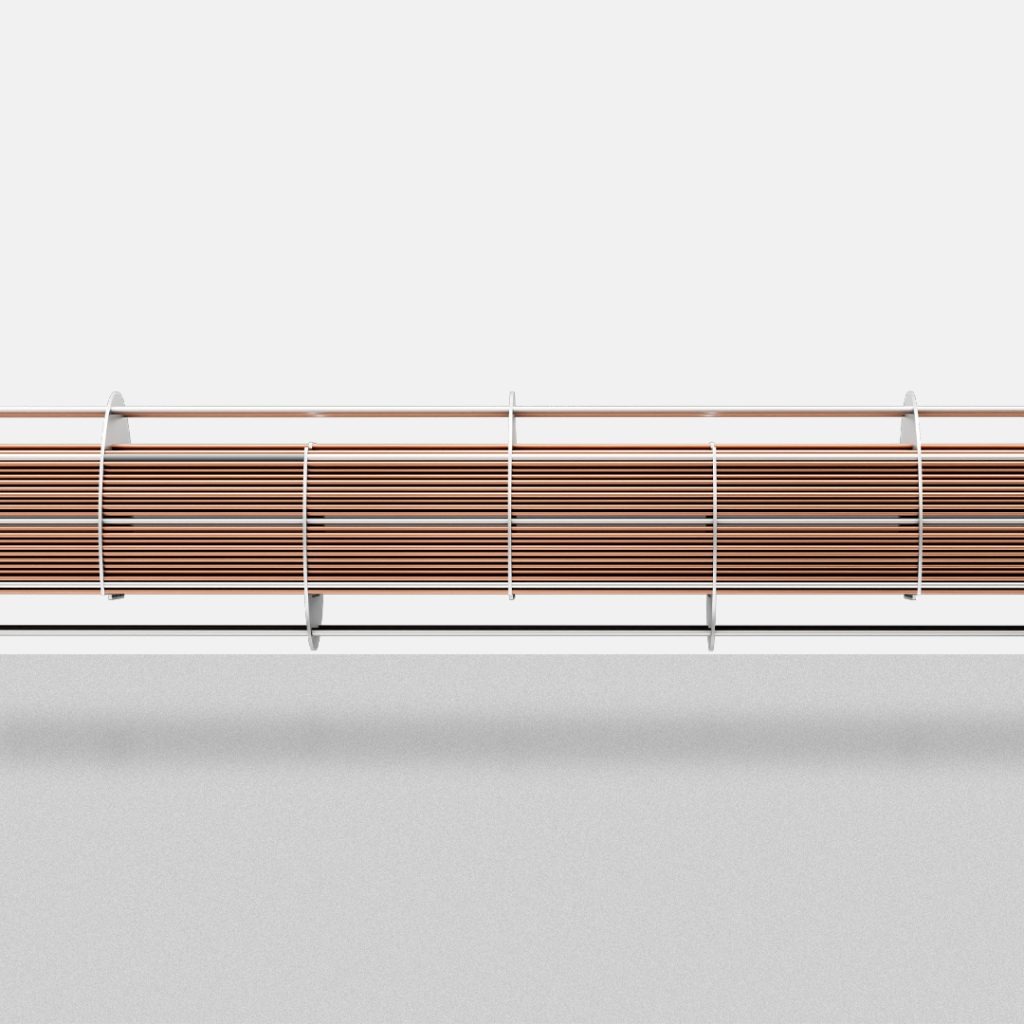

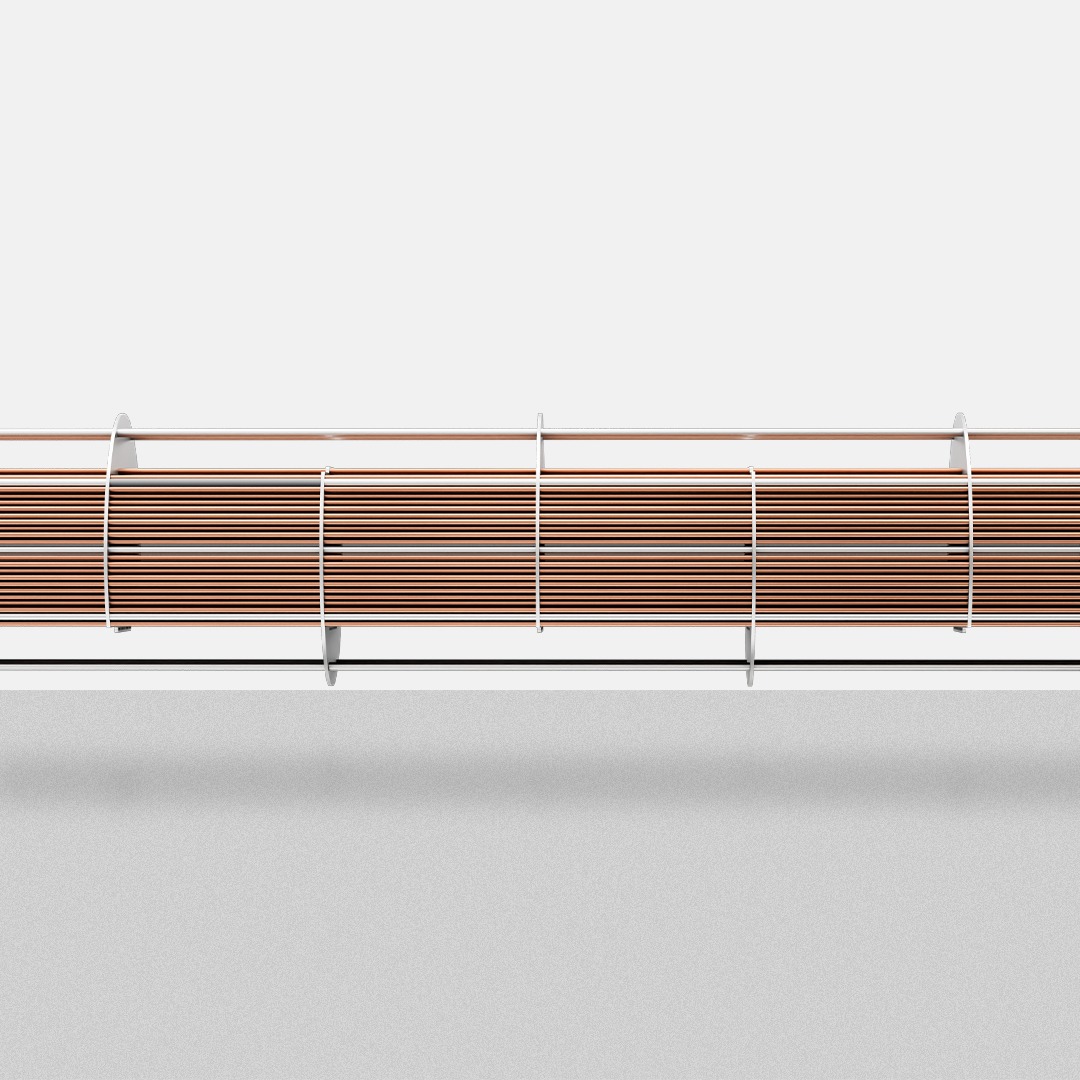

Evaporators can be designed in different types depending on the type of gas used and the working pressure. Evaporators are manufactured using internally grooved copper tubes as standard. Depending on the type of fluid, they can also be manufactured with stainless or copper-nickel (bafon) tubes, galvanized or stainless body.

Advantages of Evaporators:

- High Energy Efficiency: Provides maximum performance with low energy consumption and reduces operating costs.

- Durable and Long Lasting Design: Built to withstand harsh industrial conditions, ensuring long-term use.

- Wide Area of Use: It can be used in many sectors such as air conditioning, food industry, petrochemicals, iron and steel.

- Environmentally Friendly Technology: Provides sustainability with environmentally friendly production processes and cooling solutions.

- Easy Installation and Maintenance: The modular design offers operational simplicity with easy assembly and minimal maintenance requirements.

- Flexible Capacity Options: It offers solutions suitable for all kinds of needs with its models in different capacities.

- Improved Heat Exchange Efficiency: High efficiency is achieved in cooling processes thanks to effective heat exchange.

- Wide Product Range: It provides solutions suitable for every sector with its various models and features.

- Use of Advanced Technology: Evaporators manufactured using state-of-the-art technology comply with the latest engineering standards.

- High Reliability: Tanpera Inc. offers reliable and high quality products with its long years of experience.

Why Use Evaporators?

In order for industrial and commercial refrigeration systems to operate efficiently and reliably, the use of the right heat exchange elements is critical. At this point, evaporators are one of the most essential components of the cooling system. The success of a cooling system directly depends on the efficient operation of the evaporator. This is why TANPERA TES Series Evaporators should be preferred:

- High Heat Exchange Efficiency: Evaporators are components that directly affect the energy efficiency of the refrigeration system. A high-performance evaporator provides more cooling with less energy consumption, which significantly reduces operating costs.

- Precision in Temperature Control: Many industrial processes require precise temperature control. Evaporators maintain the desired temperature levels by converting the refrigerant into the gas phase, thus ensuring stability in production processes.

- Various Application Areas: Evaporators can be used in a wide range of applications from air conditioning systems to the food industry, from petrochemicals to pharmaceuticals. It offers effective solutions in almost every sector with different design and material options.

- Long Life and Durability: TANPERA TES Series Evaporators are built to withstand harsh operating conditions. Quality materials and superior engineering ensure long-lasting use, which increases the reliability of the system.

- Easy Maintenance and Flexibility: Thanks to their modular structure, evaporators are extremely easy to install and maintain. In addition, it offers solutions suitable for all kinds of needs with different capacity and material options.

Evaporators are the heart of a refrigeration system and, when selected correctly, directly improve the overall performance and energy efficiency of the system. TANPERA TES Series Evaporators are advanced technology products that respond to all these needs.